The most commonly used desiccant in packaging is silica gel. Silica gel is a milky white or translucent amorphous granular material with a porous high surface area structure. It is non-toxic, tasteless, hard in texture and not easily broken. The surface of the silica gel is covered with hydroxyl groups, so it has strong hygroscopicity, but it is insoluble in water, and has high thermal stability and chemical stability. These properties of silicone are more in line with the requirements of moisture-proof packaging.

There are many types of silica gel. Fine-silica gel with a pore diameter of 1.0-2.0nm is often used in moisture-proof packaging. In the moisture-proof packaging of precision instruments, it is best to use spherical silica gel to prevent falling powder and scratching the surface of the product.

In order to directly observe the degree of hygroscopicity of silica gel, silica gel is often treated with chlorinated diamond solution to make discolored silica gel. The dry state of this color-changing silica gel is blue, and it will turn light red when the moisture absorption is higher than 40%. The primary color silica gel can also be mixed with some color-changing silica gel to indicate the degree of moisture absorption of the silica gel.

After the silica gel absorbs moisture, it can be dehydrated and regenerated by heating.The hygroscopic isotherm of silica gel is used repeatedly (at a certain temperature, the relative humidity and the equilibrium moisture of the silica gel are plotted).The change with temperature is very small, that is, The hygroscopic capacity of silica gel is less affected by temperature, so the humidity in the packaging container will not change drastically due to temperature changes.

In recent years, a new type of desiccant has appeared abroad. This kind of desiccant uses a natural clay as a raw material. After physical treatment and heating and drying, it obtains off-white solid particles. The main components of this clay are silica and alumina. This clay was first discovered in France and used in moisture-proof packaging of French military supplies. Later, this clay was also found in the United States, and it was manufactured in large quantities in desiccants and used in moisture-proof packaging for military precision instrument machinery, weapons and electronic industrial products. This kind of desiccant has strong drying ability, good stability and excellent texture. It is widely used in the United States, France, Japan and other countries. The main components of this desiccant are shown in the table below.

The main component of clay desiccant%

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO |

| 61.5 | 17.3 | 1.67 | 2.71 | 6.51 |

Molecular sieves can also be used as packaging desiccants. It is often used for pre-drying nitrogen during storage in a nitrogen-filled environment.

Activated alumina, calcium chloride, magnesium perchlorate, etc. can also be used as packaging desiccant. Fully dried paper products can also be used as desiccants.

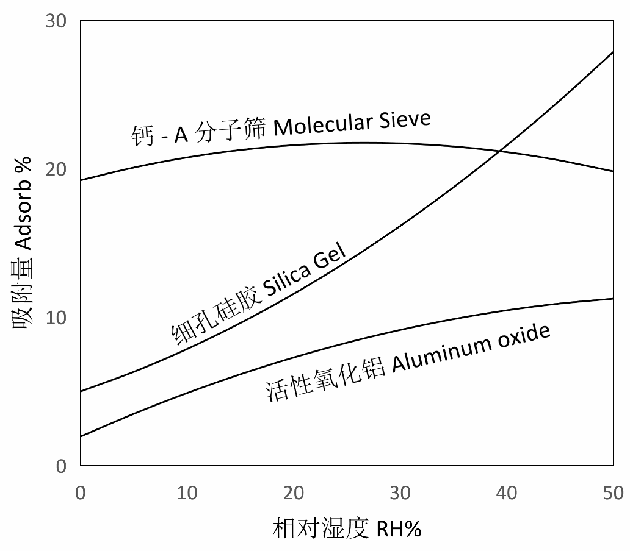

In practical applications, the two desiccants are often used in combination. For example, when pre-drying nitrogen by the dynamic method, you can first pass nitrogen through a calcium chloride desiccant with poor drying ability, and then pass nitrogen through a silica gel desiccant with strong drying ability; when static drying (place a desiccant in a packaging container) , You can also use two desiccants at the same time, not only save desiccant, but also maintain a certain drying effect. The figure below shows the relationship between the relative water vapor adsorption capacity and relative humidity of several desiccants at 25℃.

* From《包装材料学》ISBN 7-80000-541-0